By Lee Sibley

4 years ago

By Lee Sibley

4 years ago

Computer chips: the inside story

Porsche has been facing major delays to delivery times of its vehicles in 2021 and 2022. So what's the problem? And how long is it set to last?

In simpler times, a ‘chip shortage’ at Zuffenhausen meant factory workers couldn’t enjoy a helping of fried potatoes with their lunchtime currywurst. Today, the whole car industry is reliant on semiconductor chips – and shortages lead to production delays and millions in lost revenue.

In this article, we’ll explain what these chips are, where they are used and how the current crisis affects Porsche. And all without a spiced sausage in sight…

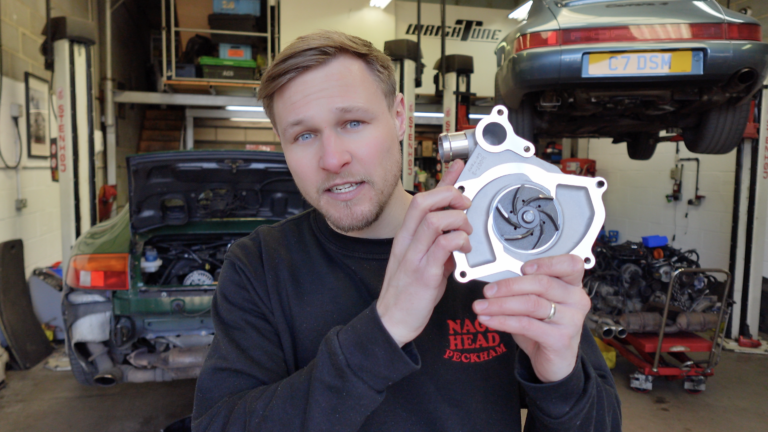

What are semiconductor chips?

The story of semiconductors starts with the invention of the transistor in 1947. However, it was the arrival of the integrated chip in 1967 that kick-started mass production. Semiconductor chips became essential to the nascent computer industry – and their use has increased exponentially ever since.

A semiconductor passes an electrical current more easily in one direction than the other. They are an essential part of computer processing and memory chips, along with components such as switches and sensors. As the automotive world embraces electrification and connectivity, they’re now an essential part of cars, too.

Categories

How are semiconductor chips used in cars?

The shift towards hybrids and electric cars is the most obvious manifestation of electrification, but semiconductors inhabit every area of a new car. They help reduce energy use in systems such electric steering and LED headlights, slashing CO2 emissions and boosting EV range. They’re also a key part of active safety tech, such as adaptive cruise control and automatic emergency braking.

Then there’s infotainment. Once upon a time, Porsche buyers were lucky to get an AM radio. Now cars are constantly connected to the internet and process huge quantities of data in real-time, from traffic info to over-the-air updates. ‘Car-to-X’ communication between individual vehicles – to warn nearby drivers of a hazard ahead, for instance – is also becoming commonplace.

What has caused the chip shortage?

There is no single cause of the chip shortage. Back in May, Uwe-Karsten Städter, Porsche’s then head of procurement, cited factors as diverse as the coronavirus pandemic, the blockage of the Suez Canal and a drought in Taiwan (where many semiconductor chips are made). The explosion in home working, and consequent demand for consumer gadgets, has also played a part.

Car manufacturers have fallen victim to their lean production processes, too. Pioneered by Toyota and now de rigeur throughout the industry, just-in-time (JIT) production demands regular deliveries of parts in small quantities – rather than storing components on-site. It minimises the investment in stock, but factories can quickly grind to a halt if important parts don’t arrive.

How does the problem affect Porsche?

If you have a new Porsche on order, you may face a long wait. However, according to Rob Durrant of Porsche’s UK press office, the chip shortage isn’t the main issue. “There are a few strands to it,” he explains. “Covid is still having an intermittent effect, semiconductors are there too, and we have an unprecedented demand in the UK, which is probably the single biggest contributor.”

Durrant also says delays are very model-specific. The new 992 GTS, for example, has a “fairly standard” lead-time of six months, while a 992 Carrera buyer may wait a year. “That’s the same situation for all our model ranges. As everything is so specific, dealers are working with customers individually as it’s by no means a blanket scenario.”

How is Porsche combating the chip shortage?

For a short while, Porsche used non-functional dummy chips for some car components, then retro-fitted the correct items afterwards. More broadly, the company has harnessed artificial intelligence (AI) to tackle problems in the supply chain. A cloud-based system called Catena-X uses a complex algorithm to analyse publicly available information ‒ including social media – in more than 50 languages, then highlights potential hold-ups before they happen. The system is used by other brands in the Volkswagen Group, plus rival manufacturers such as Mercedes-Benz.

Ironically, then, the solution to building connected cars efficiently is greater connectivity. Because whether you prefer your Porsche with a flat-six or an electric motor, we’re all hooked on chips.

Article written by Tim Pitt